SPONSORED CONTENT - Globally, there is a shift in consumer support toward conscious brands that have commitments to equitable workplaces, sustainable fabric choices, and intersectional environmentalism.

According to Edited, a leading retail market analysis group, sustainable activewear for menswear increased 65% year-over-year (2019-2020), while womenswear is up 45% in the category. Soon, this segment will make up the majority of the buying public for any season and garment type.

Going hand-in-hand with the need for sustainable fibers and fabrics is the need for transparency. In a survey from McKinsey & Co, “Sustainability and Transparency” was ranked #1 by over half of all executive respondents as the priority for sourcing at scale.

“Even before the pandemic, we saw an increased demand for traceability and transparency throughout the value chain,” says Global Brand & Communications Leader Alexa Raab. “We introduced our Common Thread Fabric Certification at the start of Q2 2020 to reduce haziness in the supply chain and work with mill partners to create certified fabrics that have a minimum amount of bio-based content and meet strict performance requirements.”

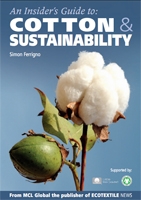

By integrating Sorona® polymer in a fabric, it is possible to offer real solutions that contribute to a powerful circular economy. Made from 37 percent plant-based materials, Sorona® is a high-performance fiber and a key ingredient in clothing from some of the world’s most popular brands that are using it for everything from insulation to swimwear, and compression shoe uppers to comfort stretch fabrics. Its superior performance qualities are transforming the way apparel companies think about the viability of renewable ingredients.

Biomaterials are no longer the “green but underperforming” products of the past. Sorona® is an excellent example that renewable and sustainable ingredients deliver on performance expectations. “We believe any biomaterial must not only be accessible and scalable, but meet or exceed performance expectations of the incumbent product,” says Raab. With its superior shape recovery, breathability, ultraviolet protection, and long-lasting fit retention, fabrics made with Sorona® are made to last. Once the garment has reached its end of life, Sorona® is also recyclable, meaning it will be a key player in the successful transition to a circular economy.

The benefits extend beyond the resulting fiber with a lower environmental footprint in the production process. “The fundamental process to make bio-propanediol (Bio-PDO) from industrial dent corn is the same fermentation process that is used to make beer and the entire process from corn harvesting to Sorona® production is carried out in the U.S.,” says DuPont Biomaterials Product & Global Application Development Principle Investigator Samit Chevli. This means the production of Sorona® uses 30-40% less energy and releases 56-63% fewer greenhouse gas emissions than the production of nylon 6 or nylon 6,6.

The UN Sustainable Development Goal 9 and Goal 13 report, “Carbon dioxide (CO2) levels and other greenhouse gases rose to new records in 2019. Innovation and technological progress are key to finding lasting solutions to economic and environmental challenges such as increased resource and energy-efficiency.”

With its lower environmental impact, excellent performance and contribution to the circular economy, textiles made from renewable plant materials like Sorona® are the solution for companies committed to making the industry a cleaner place.